Industries

ArmorMax meets the challenge — satisfying the most demanding refractory application needs under the safest possible conditions.

View AllIndustries

ArmorMax meets the challenge — satisfying the most demanding refractory application needs under the safest possible conditions.

View AllSteel Furnaces

Turnkey solutions for reheat and tunnel furnace refurbishment, engineering, materials, installation, PCW refractory panels and systems, structural steel modification, custom ceramic fiber modules, refractory lined components, precast shapes.

Read MoreSteel Melt Shop

Custom-designed and custom-fitted refractory lined components, preheat stations and covers, ladle lids, tundish covers, precast shapes, ceramic blanket covers, ladle lining board, off-site repair and refurbishment.

Read MoreSecondary Aluminum

Refractory removal, major relines, hot cleaning, minor maintenance repairs, precision belly band repair, soaking pit relines, pier replacement, melter and holder door relines.

Read MoreThermal Oxidizer-RTO

New large structure RTO lining, field maintenance and repair, ceramic module fabrication and installation, media replacement, structural metal repair.

Read MoreForging

Refractory lining patch and removal for various furnace types, ladle and fore hearth services.

Read MoreHeat Treatment

Turnkey design and build, major relines, cleaning for survey, mechanical repair, door fabrication and installation, preventative maintenance.

Read MoreFoundry

Refractory removal, full relines of ladles, crucibles, cupolas, and induction furnaces.

Read MoreOther Industries

ArmorMax serves many additional industries including boiler, chemical, power generation, glass, and general industrial — anywhere chemical and heat resistance is needed.

Read MoreTurnkey Services

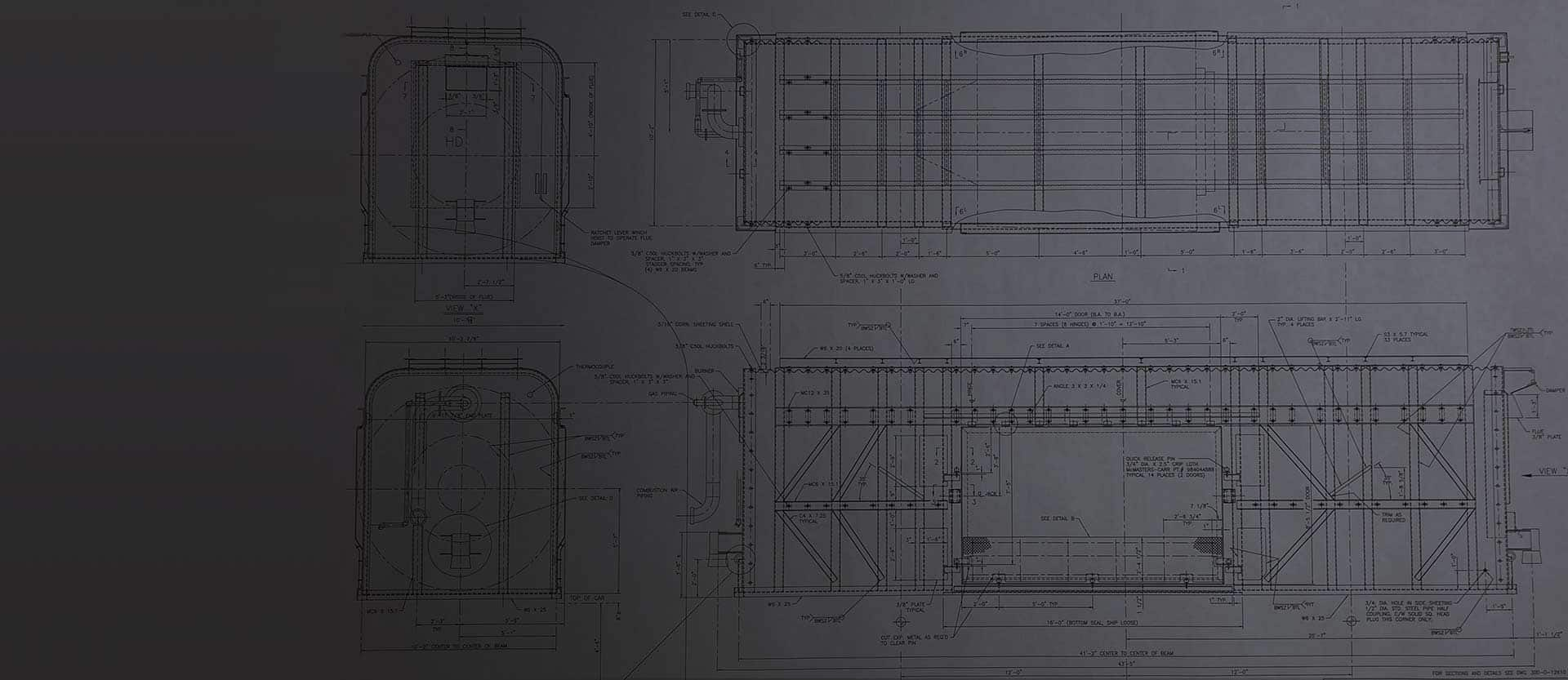

Engineering & Design

Engineering & Design

ArmorMax offers turnkey design and installation of all refractory applications. Our range of services includes refractory lining for new and existing applications for a variety of industries

Read More

Refractory Install

Refractory Install

Our highly skilled installers focus on safety and quality above all — ensuring superior refractory performance under the safest conditions possible.

Read More

24/7 Emergency Response

24/7 Emergency Response

ArmorMax provides emergency service and materials across the East Coast, Midwest, and Southern states through our six strategically placed stocking locations.

Read More

Fiber Lined Components

Fiber Lined Components

ArmorMax provides engineered and custom-fitted refractory solutions along with off-site repair and refurbishment of refractory lined components and equipment.

Read More

Refractory Material

Refractory Material

ArmorMax offers the widest range of refractory materials available. From high temperature ceramic fiber to specialty brick, gunning or castable refractories, we provide cost-effective solutions to meet all application requirements. Our warehouses are stocked with a full line of materials ready for immediate shipment.

Read MoreIntroducing ArmorWool™

A revolutionary insulation product line using next-generation technology to act as a shield – and provide superior performance – for your high-temperature insulating needs.

View All

Blanket

ArmorWool™ blankets offer many benefits, including proven technical solutions, low shot technology, excellent insulation performance and thermal stability, high handling strength and more.

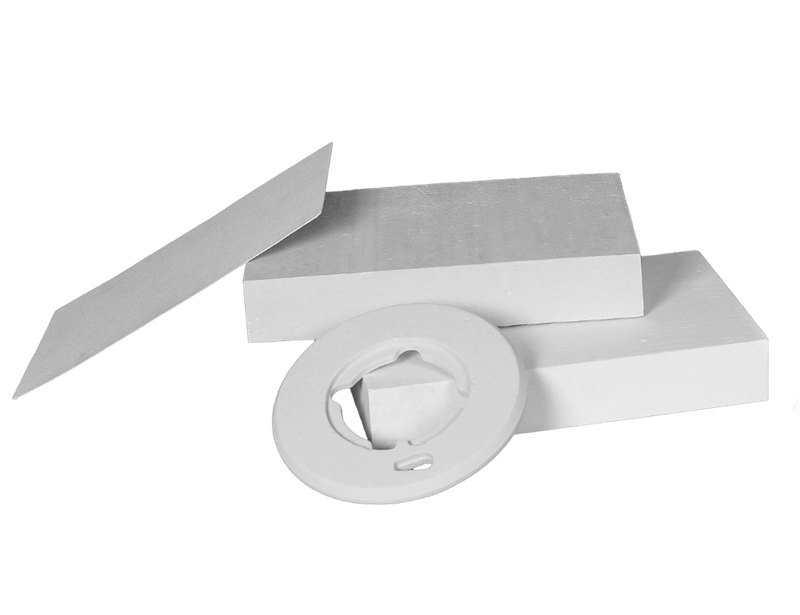

Boards

ArmorWool™ boards benefits include high temperature resistance and low shrinkage, resistance to erosion from high velocity gasses, excellent thermal insulation performance and more.

Papers

ArmorWool™ papers include a wide range of benefits, including high fiber index, low shot technology, smooth surface and low dust, excellent insulation performance, and more.

About Us

Superior Turnkey Refractory Solutions — Expertise in the Design, Installation, and Supply of Refractories, Components, and Industrial Insulation. Our experienced refractory service team provides custom engineered solutions and employees removal and installation practices that ensure worker safety, reduce operating cost and shorten maintenance downtime. ArmorMax meets the challenge — satisfying the most demanding refractory application needs under the safest possible conditions.

Read More